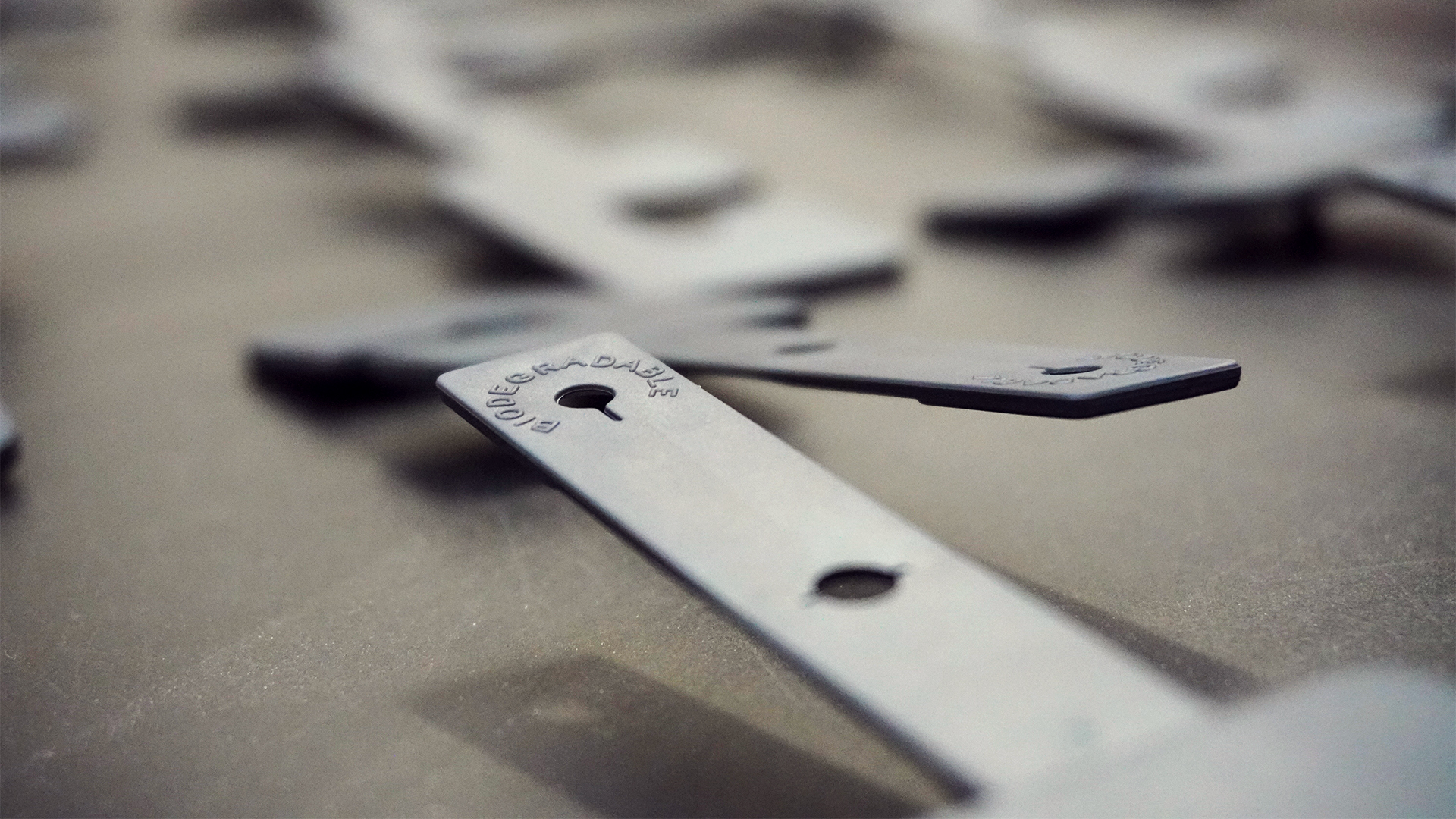

Plasti-Max group has always operated in the field of injection molding of thermoplastic materials.

Plastic can turn up in different variants with different technical and aesthetic performances depending on the molding properties. However, in the table below – which is not meant to be a technical/scientific study but a generic guide – we have tried to identify the main types used for our products, indicating their aesthetic appearance and the main mechanical properties that determine their use.

| Material abbr. | Description | Appearance | Mechanical Properties | Disposal code |

| PS | Polystyrene | Trasparent |

Hard and Weak Possibility of adding a modifying substance which gives better performance in case of impact (HIPS), losing transparency |

|

| PP | Polypropylene | Translucent |

Elastic and Resistant High tensile strength, high ductility, low density, excellent thermal and abrasion resistance |

|

| PC | Polycarbonate | Trasparent |

Hard and Resistant Exceptional resilience, heat resistance, transparency, sterilizability |

|

| PE | Polyethylene | Milky white |

Ductile and Flexible, not elastic Excellent electricity insulating properties |

|

| PMMA | Polymethyl – methacrylate | Trasparent | Unbreakable, excellent optical properties, UV resistant (softer than PC) |  |

| ABS |

Acrylonitrile Butadiene Styrene

|

Trasparent / Opaque | Each monomer gives different properties, based on the composition we can find: medium and high resilience, limited or high surface brightness, high heat deformation. |  |

Mainly, an article is assigned the material that best expresses its technical characteristics. However, only for some product categories, the material can be chosen by the customer according to his needs: based on the degree of rigidity, resistance, or aesthetics that we want to obtain, we can evaluate together the alternative material that best reconciles the two aspects.

As you could see, the materials we deal with are many and of every type belonging to the plastic world (and alternatives to it). Our production always tries to keep up with the times, for this reason we have also introduced bi-component presses, therefore capable of printing and coupling two different materials.

Whatever your idea or need, we will surely find a way to make it happen – so do not hesitate to ask us for an opinion, we will be happy to support you in developing a new project together.